Potest superficiem coating technology de Carbon Steel percutiens ancoram effective resistere eget corrosio?

2025-04-23

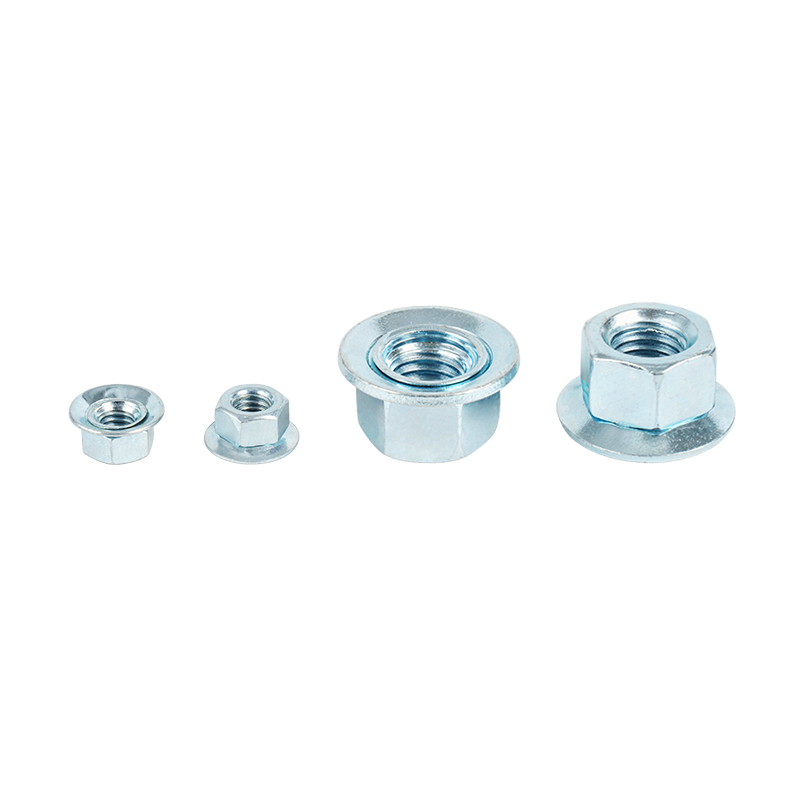

In agro industria et constructione: Carbon Steel Percute ancoris Est clavis onus-afferentem component, quae est patere universa environments diu. Chemical corrosio est unum de principalis causas eius defectum. In annis, superficiem coating technology est late ad amplio eius corrosio resistentia, sed hoc technology vere efficenter resistere eget corrosio?

I. Tutela mechanism coating technology: multi-gradu obice et eget passivatio

Et corrosio-repugnans coating technology de Carbon Steel ancoram Bolts maxime includit duo core machinationes: Physica Protection et eget passivation praesidium:

Physica Otio Layer: Per calidum, intinge galvanizing, epoxy resinae spargit aut fluorocarbon coating et aliis processibus, a densa coating formatur super superficiem subiecti instrumentis (ut Cl⁻, So₄²⁻) a recta contactus. Exempli gratia, in Porosity fluorocarbon coating est minus quam 0,5%, quod potest significantly reducere pereability.

Chemical Passivation Efféctus: Zinc-secundum coatings (ut calidum, intinge galvanizing) mora substratam corrosio per Cathodicam praesidium sacrificii Anodorum; Dum chromate, quibus epoxy coatings generate firmum cadmiae films (ut crito₃) in metallum superficiem per passivation reactiones, inhibentes electrochemical corrosio reactions.

II. Experimentalem comprobatio: Quantitative notitia de coating perficientur

Laboratory accelerated corrosio probat ostendere quod superficiem coatings potest significantly extend in vita Carbon ferro ancoras seras:

Salis RAMULUS Test (ASTM B117), uncoated Carbon Steel ancoram Bolts develop rubrum rubigo intra LXXII horis, dum exempla cum duplici de primario ratio est magis quam 2,000 et corrosio rate reducitur plus quam XC% et rate reducitur plus quam XC%.

Acidum et alcali immersionem experimentum: in H₂so₄ solutio cum PH de III, in corrosio pondus damnum rate of fluorocarbon iactaret ancora fulmine non solum 1/15 et cortices, et coating non facit binorum vel excorio.

Electrochemical impeditance spectroscopy (Eis), in impedimentis modulo de coating ratio potest pervenire magis quam 10⁶ ω · CM², significans quod est optimum resistentia ad Ion penetrationem.

III. Practical applicationem casibus: perficientur verificationem in extrema environments

Offshore Platform Application: A Marine Project Uses Hot, Tread Galvanized epoxy signantes coating carbon ferro ancoras. Post servientes in marine atmosphaera quibus sal imbre et excelsum humiditatem VIII annis, non est visibilis corrosio in subiecto, et coating adhaesionem supra XCV% (probata per crucem-interficiam modum).

Chemical Plant Corrosion Protection: a eget plant reactionem turrim fixum ancoris fulmine utitur polytetrafluoroethylene (Ptfe) coating. Sub condicionem contactus cum fortis acidum (concentration XXX% HCL), ibi est non coating defectum vel subiecta sub V annis, et sustentacionem sumptus reducitur per LXX%.

IV. Technical More directionem et suggestiones

Etsi existentium coating technology habet significantly amplio ad corrosio resistentia carbonis ferro ancoras seras, sequenti quaestiones adhuc opus est solvit operam ad:

Composing matching: Select in coating system secundum genus mordax medium (ut PTFE est malle in acidic amet, et epoxy resinae apta est alkaline environment).

Construction processus imperium: coating crassitudine, curing temperatus et superficiem preteratment (ut sandblasting ad sa2.5 gradu) protinus afficiunt tutela effectus.

Vita exolvuntur Custus: Initial investment of princeps-perficientur coatings (ut fluorocarbon) est princeps, sed non potest reducere sumptus postea postea et sustentacionem, et comprehensive sumptus est commodius.

Ex experimentalis notitia et ipsa engineering perficientur, superficiem coating technology de Carbon ferro ancoras seras potest efficaciter resistere chemical corrosio, et tutela effectum pendeat in lectio de coating materiae, processus imperium et environmental adaptability.