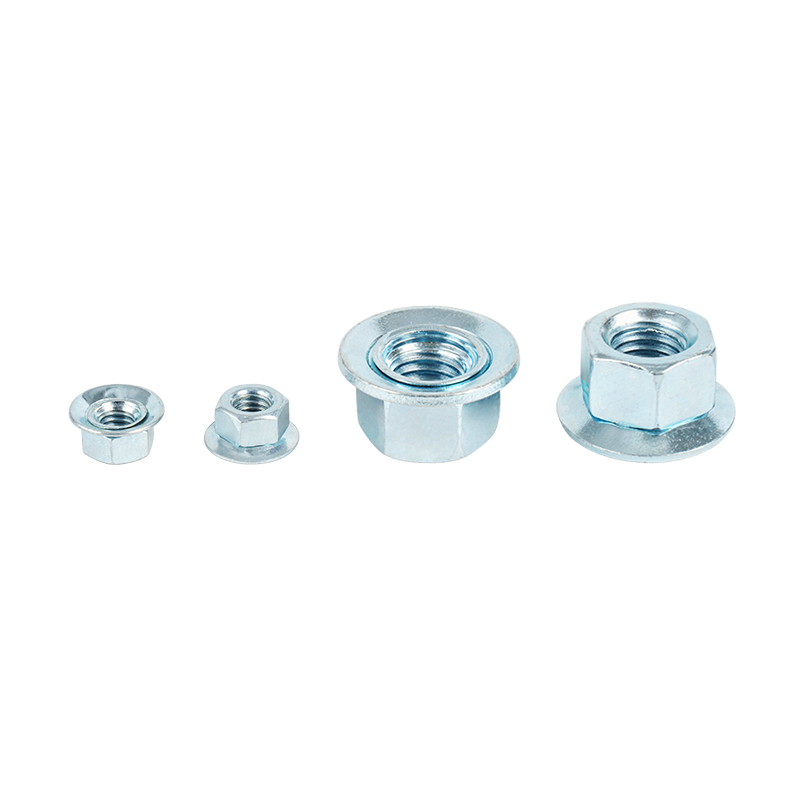

Carbon Steel Strike ancoram: Bancmardo et sumptus-effective arbitrium in gravibus-officium ancoris

2025-03-21

In gravibus-officio ipsum agros ut tecta, pontes, et industria facilities, ancores sunt clavis nodis ad structural salutem, et eorum materia lectio directe afficit ad reliability et oeconomia in project. In annis, Carbon Steel Percute ancoris Habet cursim replaced traditional immaculatam ferro, ally ferro, et plastic ancoras in global summus finem engineering foro cum suis unique perficientur commoda, becoming malle solution ad engineers.

Mechanica perficientur commoda carbonis ferro percutiens ancoras caule ex pressius imperium ally componat. ASTM A449 Latin Carbon Steel quod est exemplum, eius tensile vires potest pervenire magis quam 1200mpa, et cedere vires excedit 1000mpa, longe excedens CCCIV ((VI) LXI Aluminium (Tensile Vesalius 310MPA). Potius per, per extinxit et temperatio processibus, carbon ferro anchors potest ponere princeps vires dum moderando eorum elongationem in range of VIII% -15%, efficaciter vitandum periculum fragile fractura.

In dynamic onus test, in lassitudine vitae carbonis ferro impulsum ancora seras pervenit X ^ VII Cycles (onus amplitudine ± 400mpa), quod est 2.3 temporibus, quae Ordinarius immaculatam ferro ancori. Exempli gratia, in Offshore Ventus Power Projects, Carbon Steel ancoras Bolts feliciter Transierunt Typhoon-Level Ventus Vibrationis simulation test et eius industria dissipatio coefficiens pervenit 0,85, quod significantly melius quam alia materiae.

Et corrosio resistentia defectus de traditional ipsum ferro fuisse novis per modern superficiem ipsum. Et carbon carbon ferro impulsum ancora pudoris capere multi-iacuit compositum praesidium ratio:

Base Donec Shoulder: Hot, Tread Galvanizing (cadmiae accumsan crassitudine ≥85μm) vel Dacromet coating (crassitudine 6-8μm), Salis spray Test vitae excedit M horas;

Eget firming accumsan: Nano-Ceramic coating (ut alno₃-tio₂ compositum coating) praebet chemical stabilitatem in ph3-11 environment;

Intelligentes Restituo Layer: MICROPAPSULE SECRETS STABES technology potest actively dimittere corrosio inhibitors cum coating est laedi.

Comparative experiments show that in the marine atmosphere (Cl⁻ concentration 1.5mg/m³), the corrosion depth of the triple-protected carbon steel anchor bolt after 20 years of service is only 0.12mm, while the local corrosion depth of the 316 stainless steel anchor bolt caused by pitting is as deep as 0.35mm. Hoc technological breakthrough habet enabled ipsum ferro ancoras seras ad prospere intrare dure missionibus ut Offshore tabulatis et eget pipelines.

Ex perspective of Engineering Teubneriana, Carbon Steel Impact Anchor Bolts Show praeclara Sumptus Imperium Capabilities:

Purchase Custus: XL% -60% inferior quam immaculatam ferro ancoras seras eiusdem speciei, et magis quam LXXV% inferior Titanium Alloy anchoram seras;

Installation efficientiam: et patented expansion pyramidis consilio reduces installation torque per XXX% et crescit cotidie constructione volumine per L%;

Sustentationem sumptus, sub equivalent protectione gradu, in XXX-annus sustentationem sumptus de Carbon ferro ancoras fulminibus non solum 1/3 illius de immaculatam ferro products.

Taking a crucem-mari ponte ancoris project ut exemplum, in usum carbonis ferro impulsum ancora fulminibus pro originali stainless ferro solution reducitur in altiore anchoring ratio sumptus per XXII dies, et Transierunt tertiam partem certification a L annos, et Transierunt tertiam partem certification per tempus, et transierunt tertiam partem certification a L annorum

Modern Carbon ferro percutiens anchors et developed in in magna carrier intelligentes anchoring systems. Per integrating iot components ut iactabantur sensu optical fibris et rfid eu, engineers potest monitor in preload mutationes, corrosio status et onus distribution de anchors in realem tempus. In nuclei potentia plantarum firmam anchoring project, in carbonis ferro anchor ratio embedded cum sensoriis feliciter monuit Micro-displacements ad 0.03mm gradu, avoiding potentia structural risks.